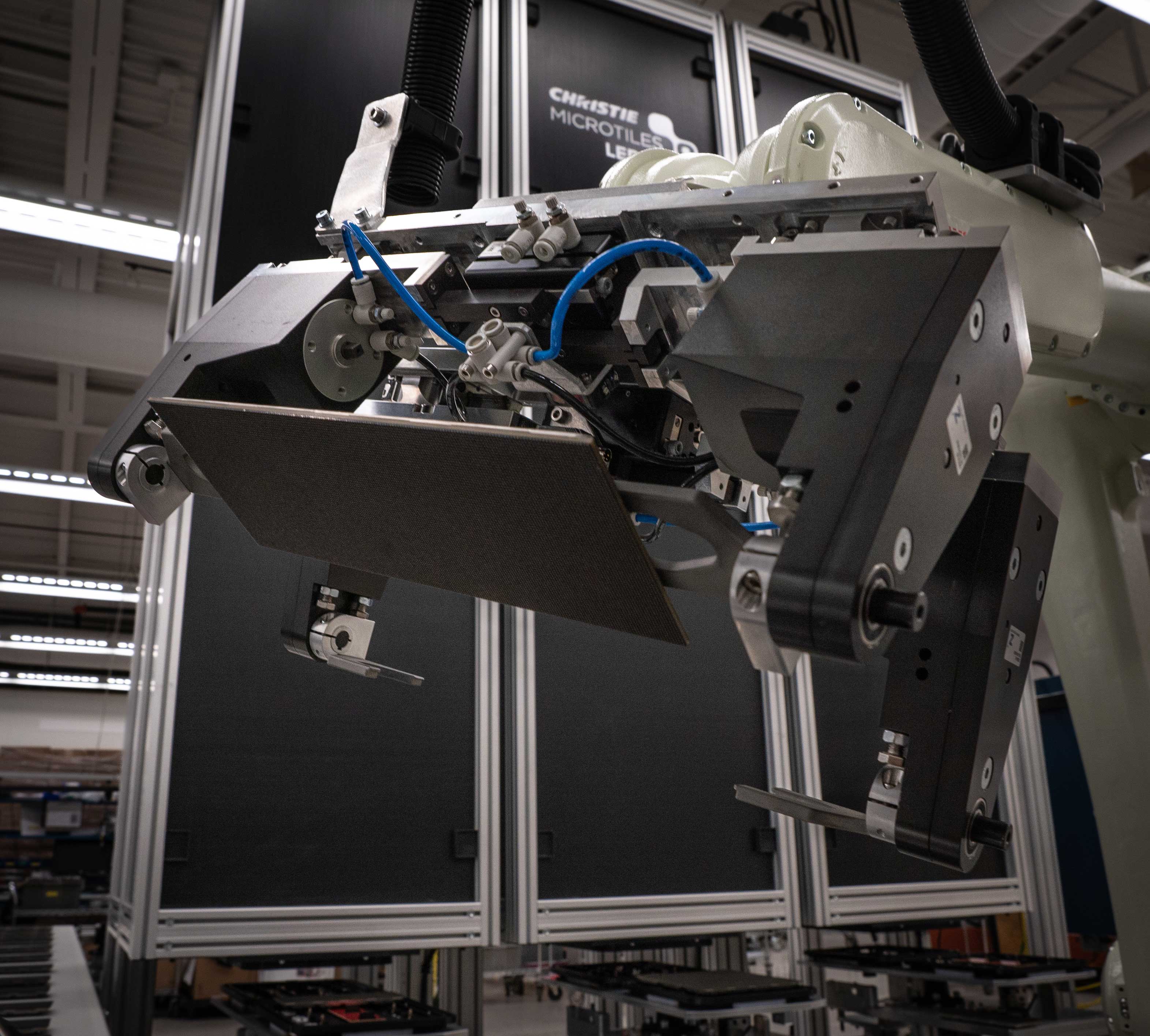

Earlier in June, Christie announced it ramped up its production facility in its Kitchener-based Center for Engineering Excellence to keep pace with increased demand for MicroTiles LED. The new space includes a state-of-the-art automation line with robotic handling, which has increased manufacturing capabilities by almost threefold. The design of the new area mirrors some of the most advanced manufacturing facilities in the world.

Why Micro Tiles LED?

Christie's award-winning MicroTiles LED deliver P3 color space, fully compliant HDR-10 and includes patented software that keeps the wall calibrated at 97% or greater uniformity. MicroTiles LED includes a low-profile ADA-compliant QuickMount system so displays can be created in any shape and size, including 90-degree inside/outside corners and both concave and convex curves.

“We’re excited to be at the forefront of incorporating advanced manufacturing processes into LED design and production,” said Shawn Mills, director of display engineering, Christie. “Ultimately, we want to deliver a product that continues to exceed expectations and meets demand, and we believe our new manufacturing space will allow us to do that.”

[New Christie Projectors Combine Performance and Reliability]

Increased manufacturing capabilities at Christie

The new area includes advanced robotics and assembly lines, capable of manufacturing Christie’s MicroTiles LED. “In production and manufacturing, there is a tendency to outsource automation,” said Mills. “By designing and building our new automation line using our in-house engineering experts, we've not only increased our manufacturing capabilities, but we've also ensured we are ready for the next stage of growth. As a result, the new space incorporates best-in-class practices, including vertical integration, which ensures we build the highest quality product for our customers.”

Additionally, two new “pick and place” robots have been installed to perform repetitive, low-level tasks, including moving tiles from conveyors quickly and efficiently. This allows Christie’s highly trained manufacturing staff to focus on more advanced tasks.

[Viewpoint: The Future is Repeatable, Dependable AV]

Mills is excited for the future, and the versatility of the team. “We can now invest even more in what's called design for manufacturing (DFM), a process used in higher volume industries, like automotive. On the team we have people that build and design the product and then naturally shift to designing the automation as an extension of this process. This gives the company a huge advantage because we can control much more of the value-chain, and we can be innovative not only in the design of the product, but also the process of creating that product. It’s as important how we make our products as what we’re making.”

With the new production facility, Christie can increase production of MicroTiles LED, and adhere to the very high standard of quality that this product is known for. “We measure every LED as they come off the line, and we make sure they hit very tight tolerances, so that the MicroTiles create a seamless canvas.”