Alan C. BrawnIn the world of display technologies nothing is more discussed than LCD flat panels versus all the hype over things like organic light emitting diode or OLED based displays. The truth about OLED is that it will become a force to be reckoned with but just not in the near term at least on the commercial display side and in large flat panel sizes. While there are a lot of reasons both technical and economic for OLED falling behind the expected and touted by many, product development and acceptance levels, it is really the good old LCD flat panel and several intermediary and evolutionary developments that is staving off OLED at this point in time and it is more of an economic set of reasons than one involving technological capabilities or necessity. Stay tuned for the economic explanations but we will start our little journey in the realm of flat panel display resolutions.

Most of us who have been around a while clearly remember the early flat panels at 852 x 480 resolution or even less for us older types and we will also recall the improvement in picture quality as we were introduced to the new and revolutionary at the time, 1920 x 1080 images. Matching great content to increased pixel density was and still is a pleasure to behold and enjoy. Keeping on track with concept of “more is better” the next great thing and the buzz of both InfoComms 2013 and 2014 was 4K. Ultimately this all boils down to pixel density so let’s explore the concept a bit for the display geeks out there.

The Samsung QMD Series feature UHD resolution, four times the number of pixels (3840x2160) compared to Full HD (1080p). The QMD Series is designed for use in settings where digital content plays a critical role in both capturing attention or delivering highly detailed visual information, including retail signage.Pixels per inch (PPI) or pixel density is a measurement of the resolution of displays. The PPI of a display is related to the size of the display in inches and the total number of pixels in the horizontal and vertical directions. For example, a 15 inch display whose dimensions work out to 12 inches wide by 9 inches high, capable of a maximum 1024×768 (or XGA) pixel resolution, can display around 85 PPI in both the horizontal and vertical directions. This figure is determined by dividing the width (or height) of the display area in pixels by the width (or height) of the display area in inches.

Display manufacturers are increasing display resolutions such as UHD 4K and retina displays, to create a higher pixel density than a typical device. This provides a “smoother” and more “real life” appearing image, by reducing the size of pixels such that a viewer with normal visual acuity at an average viewing distance cannot see a pixel. 4K UHD resolution in flat panels is a 3840 pixels × 2160 pixels compared to 1920 x 1080 for the majority of large format flat panels on the market today. Setting aside the promise of an improved viewing experience for a moment, the challenge with 4K other than the higher price per square inch is that it is hard to justify from an application perspective. There are certainly applications that do require extremely high pixel density – visualization and simulation for example, but in 95% of all other applications, 1080p, WUXGA and WQXGA resolutions actually provide images that exceeds visual acuity from appropriate viewing distances. The key words here are appropriate viewing distances. If you sit really close to a big screen there is no argument that the higher resolution the better. With all of this in mind, the question boils down to how much the viewing experience is improved and in typical viewing applications can we even see it.

The other component of the display issue is great content, without which the best display technologies are reduced if not totally negated in terms of quality and effectiveness. From a content perspective, 4K poses challenges. Excluding cinema, visualization, simulation and other specialized (read that costly) applications, it will be years before mainstream content is both rendered and efficiently delivered in the full bloom of 4K. As with so many things we deal with in our relatively new digital world, it comes down to bandwidth within a system and as we all know, that is both challenging and costly.

With the risk of getting technologically off track all of this is simply academic in a very real sense. No matter the hurdles of content creation and distribution of signals in a system, 4K is not just coming but it is here. It has begun in the consumer market and is migrating quickly to the commercial side. We cannot stop evolution from a technology and economic perspective and it is the next step for display manufacturers to continue to grow their businesses and keep the ball rolling but it is not yet all about 4K.

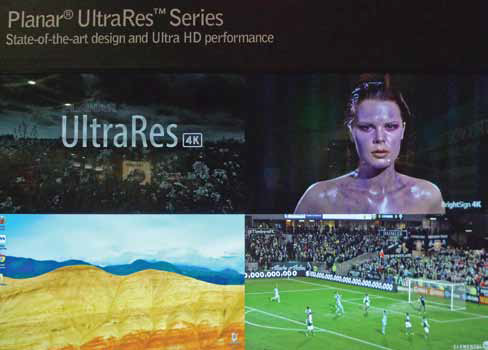

Planar’s 84-inch 4K UltraRes Touch with ERO features Corning Gorilla Glass.While we are still on that topic, the folks at Sharp have developed an interim approach (read this brilliant engineering) that takes a 1080 resolution panel and makes it look almost as good as a full 4K panel but without the manufacturing cost and end user price delta. Named the Q+ technology it has only been integrated so far into a handful of their top-tier 2014 television models so it is too early to see if it will become pervasive but we can hope. The science behind this technology is the company’s “enhanced” Full HD LCD panel, which provides ten million more pixels than most other Full HD LCD models available today. The “enhanced” panel is created by splitting each of the display’s millions of sub pixels into two, meaning each pixel has 8 sub pixels instead of 3 or 4 (in Sharp’s standard panels). The result is a Full HD LCD panel with sixteen million total sub pixels. In simple terms, the more sub pixels your display panel has, the more detail you will see, as we can use interpolated rendering to “approximate” 4K resolution quite accurately. The panels also feature independent sub pixel areas and scale to support separate color values for each area and type of content. The end result is the appearance of a higher resolution than many of the other comparable Full HD LCD panels and side by side with a full 4K panel they hold their own just less expensively.

It is time now to dig inside the layers of the LCD flat panels and look at a couple of very interesting developments that are part of the extension of the lifespan of current LCD flat panel displays and helping to stave off the onslaught of OLED. We will begin with an introduction to IGZO and no this not the name of your favorite cartoon character but the concept is pretty “techy/geeky/nerdy” as you will see.

Indium gallium zinc oxide, IGZO is a semiconducting material, jointly developed by Sharp Corporation and Semiconductor Energy Laboratories, which can be used as the channel for a transparent thin-film transistor. The benefit of IGZO is that it actually replaces amorphous silicon for the active layer of an LCD screen, and, with a forty times higher electron mobility than amorphous silicon, it allows either smaller pixels (for screen resolutions higher than HDTV) or much higher reaction speed for a screen. Also, compared to conventional displays (TFT-LCD) IGZO displays provide an increased light transmission, making smaller or fewer LEDs required for the backlight. This means that new IGZO displays are not only smaller, but also require less power. Here is where the economics comes into play. IGZO displays can be manufactured using existing LCD production lines so there is no need to build expensive fabrication plants of upwards or $400 million dollars a pop!

Remaining inside the layers of an LCD flat panel we simply must examine the exotic sounding technology known as “Quantum Dots”. Quantum dots can be built into an edge light “lamp” to be used as a backlight, or as films to adapt existing LED backlight designs, such as Nanosys QDEF™. This technology enables deep color and high efficiency by providing displays with an ideal light source. Each sheet or layer of QDEF contains trillions of tiny (a bit bigger than a water molecule but smaller than a virus in size) nanoscrystal phosphors, individually called “Quantum Dots.” These “dots” can be tuned, by changing their size, to emit light at specific wavelengths for our displays and do so very efficiently. Unlike conventional phosphor technologies that emit with a fixed spectrum, quantum dots can actually convert light to nearly any color in the visible spectrum. Quantum dots can tune the color output of the dots, by carefully controlling the size of the crystals as they are synthesized so that their spectral peak output can be controlled within 2 nanometers to nearly any visible wavelength. Pumped with a blue source, such as the GaN LED, they can be made to emit at any wavelength beyond the pump source wavelength with very high efficiency and with very narrow spectral distribution.

The dots need to be easily integrated into current manufacturing operations with minimal impact on display system design if they are to be widely adopted. To do this, Nanosys spent a lot of time working with major display manufacturers so that it would be a simple, drop-in product that did not require any line retooling or process changes. Designed as a replacement for the an existing film in LCD backlights called the diffuser, QDEF combines red and green emitting quantum dots in a thin, optically clear sheet that emits white light when stimulated by blue (some of that blue is allowed to pass through to make the B in RGB). Once again economics come into play. Manufacturers who’ve invested in equipment for LCD production can simply slip this sheet into their process, change their ‘white’ LEDs to blue (the same LEDs but without the phosphor) and start producing LCD panels with the colors and efficiencies of the best OLEDs, at a fraction of the cost and current industrial scale.

Before moving on to our last topic high brightness LCD flat panels I want to give a quick shout out to transparent LCDs. Several manufacturers have introduced lines of transparent LCD products. These LCD flat panel displays remove the backlight and light dispersion layers from behind the LCD, and move the electronics from behind the display, rendering it nearly optically transparent when showing “white” or powered off. It has various applications but the one that comes to mind is the use of the clear panel on the front of a refrigerator in retail applications dispensing beverages or any packaged product for that matter. You get to see the LCD and its changing images but can see through to what resides inside the cabinet.

It is now time to shed some light on the topic of LCD flat panels or on second thought, maybe not. As we all know, ambient light is the enemy of displays and in all cases if left unchecked, can degrade the images and thus the overall viewing experience. The answer is ambient light control and if this is not in the cards then we need a much higher brightness LCD flat panel display. The main issue with these LCD flat panels is one of brightness; most standard LCD displays we view in public spaces simply are not bright enough for the application. Now that they are finally coming into the market, high brightness LCD displays offer a major benefit compared to traditional flat panels and projection systems.

In a typical conference room where you have 30 foot candles of ambient light, a 350-400 nit LCD is fine, but outside of that kind of controlled environment, you may have many times that amount of ambient light falling on a display, necessitating a high brightness LCD. Ambient light, or the light present in an environment from all light sources, is the number one cause of degraded display performance in a system. Ambient light affects image contrast by reducing the range between the dark and bright portions of the image. Ambient light also reduces the appearance of color saturation, and degrades color accuracy.

According to SMPTE (Society of Motion Picture and Television Engineers), the ratio of display brightness and light from ambient sources should be a ratio of at least 5:1. This is necessary for the eye to perceive a real impression of brightness and contrast. This level of luminance is derived from the fact that SMPTE had historically indicated a target level of 50 FL for a television viewed under “normal” ambient light conditions of approximately 10 foot candles and although displays have obviously evolved, the rule of thumb remains valid.

The good news is that many LCD flat panel manufacturers including some of the big guys are coming out with high brightness models from 1,000 to over 2,000 nits and as an example of a leader in this niche, Dynascan offers high brightness models from 1,500 nits all the way up to 5,000 nits. As a point of reference, at the upper end this compares in brightness to direct view LED displays! Okay, I guess we can now turn back on the lights.

So there you have it. As we always preach, the only constant is change and if you take the time to dig into some of these developments, you will see where we are headed. Nobody has a 100% clear crystal ball but our current perspective and degree of clarity over the next few years is that LCD in an evolved form will continue and the trend to higher resolution and the development of specialty displays whether clear, curved, small, large or high brightness will keep us engaged and excited for the foreseeable future.

Alan Brawn (alan@BrawnConsulting.com) is a principal of Brawn Consulting LLC an audiovisual and IT consulting, educational development, and market intelligence firm with national exposure to major manufacturers, distributors, and integrators in the industry.