Integrators Can Cut DSP Programming Time And Connect More With New Offerings

The control booth at the University of Notre Dame’s Purcell Pavilion features BSS BLU-160 and 320 signal processing units.

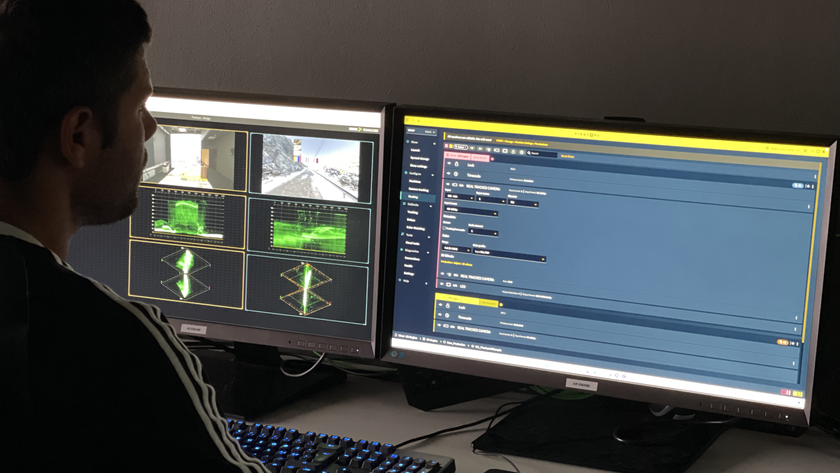

As audio DSP matrix technology has evolved, products have become increasingly more flexible and complex, leading manufacturers to host classroom and online training sessions and build comprehensive help files into their products for programmers and integrators. To further mitigate the daunting task of programming, manufacturers are working hard to streamline the process through their software interface designs.

Karl Winkler, director of business development at Lectrosonics, observes that each generation of the company’s DSP products, from the AM through the DM to the Aspen series, has become more complex but also easier to program. “We’ve worked very, very hard to make the programming language easy, or at least straightforward, so that once you get your head around what needs to be done you don’t have to keep referring to the manual every two seconds,” he said.

Further, he points out, Aspen’s Optimized Architecture feature helps guide the programmer—for example, preventing a limiter to be placed in front of a preamp. “So Optimized Architecture is a logical signal flow that’s built-in that really takes a lot of the guesswork out of it,” he said.

Matt Czyzewski, VP of business development for Biamp, also stressed his company’s drive to make its software interfaces intuitive: “I get comments all the time from people—how intuitive our interface is, how easy it is to work in, and it’s quick.”

Czyzewski pointed out that the ease with which one manufacturer’s system may be programmed compared to another’s is one of the differentiating factors: “That’s part of the competitive advantage or disadvantage; that’s a selling point.”

Every manufacturer has access to the same DSP chips. “So it’s a matter of how you implement them, how the software is put together, how the hardware goes together,” Czyzewski said.

There’s definitely a balance to be struck between retaining flexibility and imposing some boundaries that people don’t necessarily see, according to Iain Gregory, BSS/dbx market manager, installed sound, Harman International: “If you keep it infinitely flexible then all you’re doing is making it infinitely confusing.”

His company endeavors to find ways to make common tasks more easily accessible, Gregory continued. For example, “With the Room Combine object you can do what would take eight hours of programming in two minutes.”

Programming time can be somewhat offset through the ability to interconnect networked products using a single Cat-5 cable. But, noted Gregory, “It also means that you have to understand more about networks. Audio guys are having to become IT guys; but that’s happening regardless.”

Czyzewski believes that using Cat-5 cabling for almost everything in the audio system does present savings in labor and overall planning costs. “But getting everyone to recognize that has been a very slow process,” he said, because of the industry’s focus on hardware. “[People] forget that one piece of hardware may be $1,000 more than another piece, but it saves you a bunch of conduit and different types of wiring, and labor. The first time you dive into a complex system there are going to be issues you didn’t anticipate. But the next time around you’re going to be way smarter. Now, you’re getting that money back.”

Steve Harvey (psnpost@nbmedia.com) has been west coast editor for Pro Sound News since 2000 and also contributes to TV Technology and Pro Audio Review.

Margin Builder

Apple’s iPad opens up an entire new world for saving on programming costs, said Karl Winkler of Lectrosonics: “For a very low price people can get an interface that’s a blank slate, and with the appropriate software put together something rather slick that takes very little programming knowledge.”